Industrial Safety and Physical Risk Analysis Group

Industrial Safety and Physical Risk Analysis Group

6 Researchers:

Hiroumi Shiina, Ryoji Makino, Akira Matsugi, Yoshiaki Takahashi,

Makoto Asahara*(* Cross Appointment Fellow)

12 Contract Employees

Outline

In order to safely employ the attractive characteristics of energetic materials such combustible gases and explosives, their reaction behaviors must be controlled in an appropriate manner to prevent accidents. For this purpose, the capabilities to understand combustion and explosion phenomenon and to evaluate the impact of explosions on the surroundings are required. Furthermore, it is important to learn from accidents to improve safety management. To this end, our group promotes the development of technologies for the safe use of high-energy materials and the advancement of industrial safety, and we aim to meet the needs of government and society related to combustion and explosion safety, through research on 1) the safe use of high-pressure gases, 2) explosive safety and its applications, and 3) industrial safety.

Research Highlights

Safe Use of High Pressure Gases, etc.

We develop safety assessment techniques to support new technologies using high pressure gases and flammable gases such as hydrogen and new refrigerants, and we aim to realize a safe and secure society through self-managed industrial safety techniques.

Hydrogen Safety

Studies aiming to support the expansion of hydrogen utilization: Safety evaluation of hydrogen pipeline supply systems

Experimental evaluation of physical risks and hazards in hydrogen leakage, including the evaluations of hydrogen, spreading, explosion, and damages

Flame from ignition of hydrogen leaked to confined space (Ref: 2017FY, METI Project “Risk evaluation of large damage of hydrogen pipeline”)

Low-GWP Alternative Refrigerants

To assess the real scale physical hazards of residential-use air conditioners and commercial reach-in showcases, the time dependence of distributions of refrigerant concentrations were measured in a real scale model room for propane, R32 and R1234yf.

- Evaluating allowable maximum refrigerant charge

- Decreasing the propane concentrations by mixing the room-air with the fan of air conditioning equipment

Experiment conditions in a model room for natural leakage and ignition of refrigerants (Ref: 2020 NEDO “Full-scale physical hazard evaluation of

the combustion of refrigeration and air conditioning equipment using

propane considering actual use conditions” Project Report)

Chemistry-Based Evaluation of Combustion Properties

Predicting combustion properties of various gases using chemical kinetic models

- Flammable gases

- Halogenated compounds

- Oxidizing gases

Evaluating combustion characteristics based on high-temperature kinetic studies and model-based simulation

Chemical shock tube for high-temperature reaction studies |

Explosive Safety and its Applications

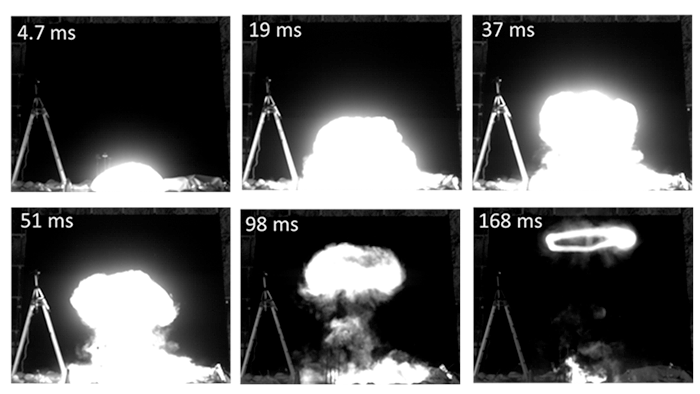

Development of Blasting Techniques

Technology that uses explosives to quickly destroy only the target area

→Controlled blasting

Blasting with smaller amounts of explosives (gram level) than before

→ Mini-Blasting

Applications

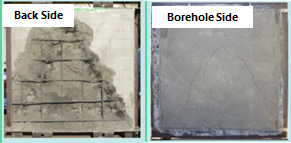

- Development of partial repair techniques for deteriorated building structures in urban areas

- Rescuing people from collapsed buildings in the event of a large-scale disaster.

Basic research for the realization of blasting technology with rapid and low environmental impact (vibration, noise, and flying debris)

→ Elucidation of explosive explosion and destruction phenomena of explosives based on optical observation such as DIC (Digital Image Correlation) method and numerical simulation technology such as CFD

Mini-Blasting Application Examples To create an opening for rescuing rescuers from a collapsed building during a large-scale disaster, so that no flying debris is generated on the rescuer’s side. |

Industrial Safety

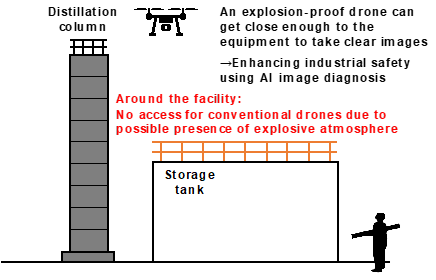

Guidelines for Explosion-proof Drones in Plants

There is a growing need for the use of drones in plants, but the law regulates their use in hazardous areas.

For contributing to the development of explosion-proof drones, guidelines on issues to be addressed and the concept of performance specifications were organized.

(from “Research on guidelines for explosion-proof drone requirements” METI Project 2020)

|

|

Economic evaluation of safety measures

In order to persuade companies to invest sustainably in safety measures, evidence of the effectiveness of such investments must be provided.

We developed methodologies and tools to assist companies in conducting economic evaluations of their safety measures in advance and in a simplified manner.

(from “Research on economic evaluation of safety measures” Japan Industrial Safety & Health Association Project 2022)

|