Explosion Safety Research Group

Explosion Safety Research Group

6 Researchers:

Shiro Kubota, Tomoharu Matsumura, Miyako Akiyoshi, Yuta Sugiyama, Takahiro Tamba

6 Contract Employees

Outline

We are conducting a wide variety of research, from basic to applied, related to explosion safety, such as safety evaluation methods and visualization techniques, technologies to reduce the effects of explosions, and safety evaluation of batteries, in order to advance the understanding of ignition and explosion phenomena of high-energy materials, as typified by explosives.

We also actively respond to the governmental needs for explosives and conduct large-scale field experiments on explosives. The results obtained are reflected in the creation of standards for safe explosives handling technology, and are also used to help formulate international standards for the handling of hazardous materials through proposals for UN testing, thereby contributing to the realization of a safe and secure society.

Research Highlights

Development of Methods and Techniques for Evaluating and Mitigating Explosion Effects

Explosion Tests in the Field

→ Contributing to the formulation of standards for techniques for handling explosives |

Detonation of ANFO explosive Ref: Report on technical standard for explosion mitigation of explosives (2016) |

Small-scale indoor experiments

- Complementing field experiments with multi-point measurements and optical visualization.

- Development of technology to reduce blast effects by buffer materials.

Optical visualization of shock front of blast wave |

Blast isobaric diagram Ref: Report on technical standard for explosion mitigation of explosives (February 2021) |

Numerical Calculation Techniques

Developing techniques for predicting effects of explosions based on numerical calculations that are highly precise and computationally fast

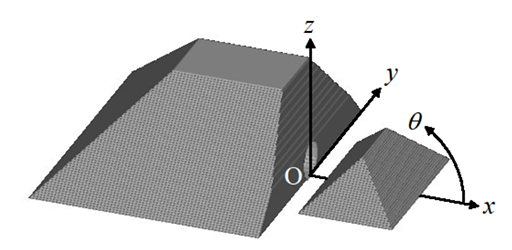

Modeling of magazines |

Simulation results of gases produced by explosion |

International contributions for explosion safety

Classification of Explosives and Energetic Materials for Safety

- Participation in TDG and GHS organized by the United Nations and international coordination of chemical substance regulations.

- Contributed to the formulation of international standards for the handling of hazardous substances by proposing MTC.

|

|

|

Evaluation Techniques for Explosion Safety for Energetic Materials

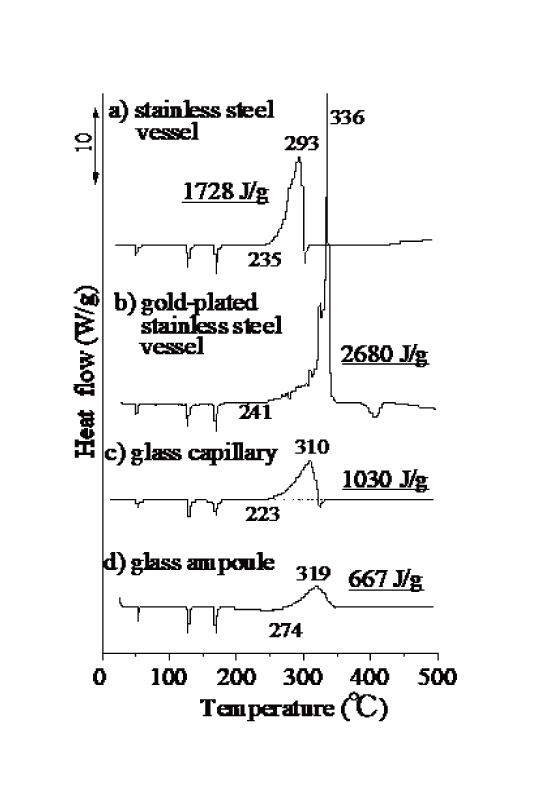

Explosivity evaluation by exothermic decomposition energy

- Development of “Method for measuring exothermic decomposition energy as a method for evaluating the explosive hazard of chemical substances, JIS K4834.

- Development of accurate exothermic hazard evaluation method for chemical substances that react with metal containers.

☛Gold plating ≠ gold

☛☛There are different types of glass containers on the market, and the results differ.

Ammonium nitrate exothermic decomposition energy

Development of advanced JIS for stability testing of explosives.

- A method for quantifying gases generated from explosives containing nitrocellulose and for evaluating the stability of explosives with high precision was added to JIS.

- Amended JIS K 4810(2023).

- Standardization of MV test method and test papers using methyl violet paper was added to JIS.

- Amended JIS K 4822(2023).

BJS test tube |

Safety evaluation of batteries

- Applied evaluation technology for safely detonating explosives to battery safety evaluation.

- Battery safety evaluation methods by evaluating thermal runaway of LIBs and gases generated in 1.5L heating vessels and 20L pressure vessels.

1.5L heating vessel |

Development of technologies for more effective use of explosives

High-Efficiency Production Technique for Detonation Nanodiamond

Development of original explosion device

→ Patent of production method at a low-cost and high-efficiency

Development of Functional Materials by Shock Compression

Light-emitting materials, carbon based materials, etc.

Synthesis of energetic materials having nanostructures

Synthesis of nano-nitrocellulose

→ Improvement of combustibility and application to new devices